Our Mission

Unlock and harness the vast resources of the

cosmos through new material processing technologies.

Photo: NASA

Welcome to Terraxis

Terraxis is a pioneering technology company driven by the potential of the commercial space economy— providing an opportunity to benefit and sustain humanity. Our mission is to unlock the vast resources of the cosmos through new material processing technologies. We are committed to developing new dual-use solutions and technologies for extraterrestrial and terrestrial resource extraction and applications. .

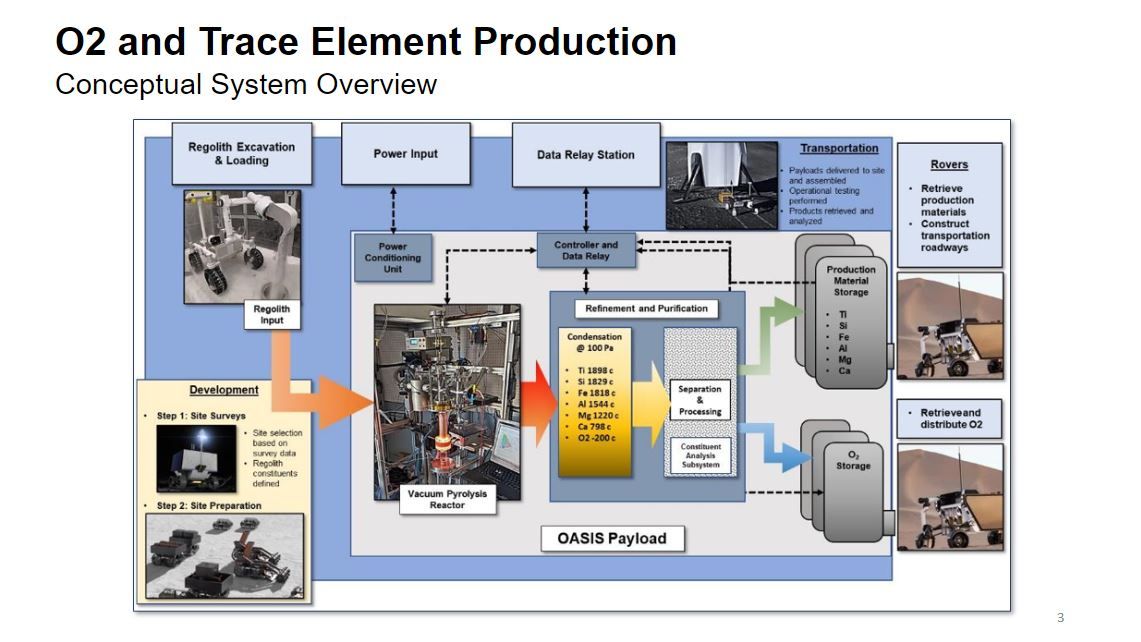

Our flagship project, the Oxygen/Resource Acquisition System In-Situ (OASIS), employs a state-of-the-art vacuum pyrolysis reactor designed to extract valuable elements from lunar regolith. With OASIS, we provide NASA and other commercial partners with the capability to support a sustained presence on the moon. The OASIS reactor utilizes inductive power transfer to superheat lunar regolith, dissociating raw minerals into component molecules such as oxygen, iron, and aluminum.

At Terraxis, we believe that the future of lunar and other planetary and asteroid commercialization depends on the efficient utilization of space-based resources. Our unique approach to resource extraction will help humans stay on the surface of the Moon longer, support more exploration and revolutionize construction of sustainable infrastructures. The implementation of OASIS facilities will allow production of major resources required for human habitation and launch site and infrastructure development.

Lunar regolith conservatively contains a minimum of 30% oxygen dependent upon location.

Our laboratory-based experiments to date show that the Terraxis reactor can make liberation of that oxygen a reality. Further, our approach can provide a key element of the infrastructure needed to support a robust lunar economy capable of in-situ production of Oxygen (O2) for fuel and human consumption along with generation of metals for use in launch pad on infrastructure development. The OASIS can provide NASA, DoD and other commercial industries the ability to support and expand a sustained presence on the Moon and beyond.

Our business plan is based on two different applications of OASIS related technology: distributed and integrated systems.

At the core for either the distributed or integrated system options are the feed system, the reactor, instrumentation, communication, control and product storage subsystems. The OASIS subsystems are envisioned to be compatible with solar panel generated direct current (DC) and fission power sources (600-3000V bus input).

Major advantages of the Terraxis reactor are that it can operate with unconditioned power and solar concentrator complexities associated with their development, transportation, assembly and operation are not necessary. It is assumed that adequate power sources will be available at any given OASIS distributed system or reactor integrated system site.

Distributed Systems

The distributed systems approach provides independent automated regolith resource extraction, processing, storage, and distribution facilities that are strategically deposited over time (much like terrestrial refineries, cellphone towers and gas stations) in multiple planned target areas. This will provide an organized method for O2 and trace element refinement to support lunar colonization, O2 generation in quantities adequate for use as O2 propellant and for human consumption as well as, raw materials for transportation network development and expansion.

Terraxis is developing the ability to capture these resources. Resulting revenue is generated based on the sale of processed O2 and raw materials from the distributed systems to the lunar economy of users.

Integrated Systems

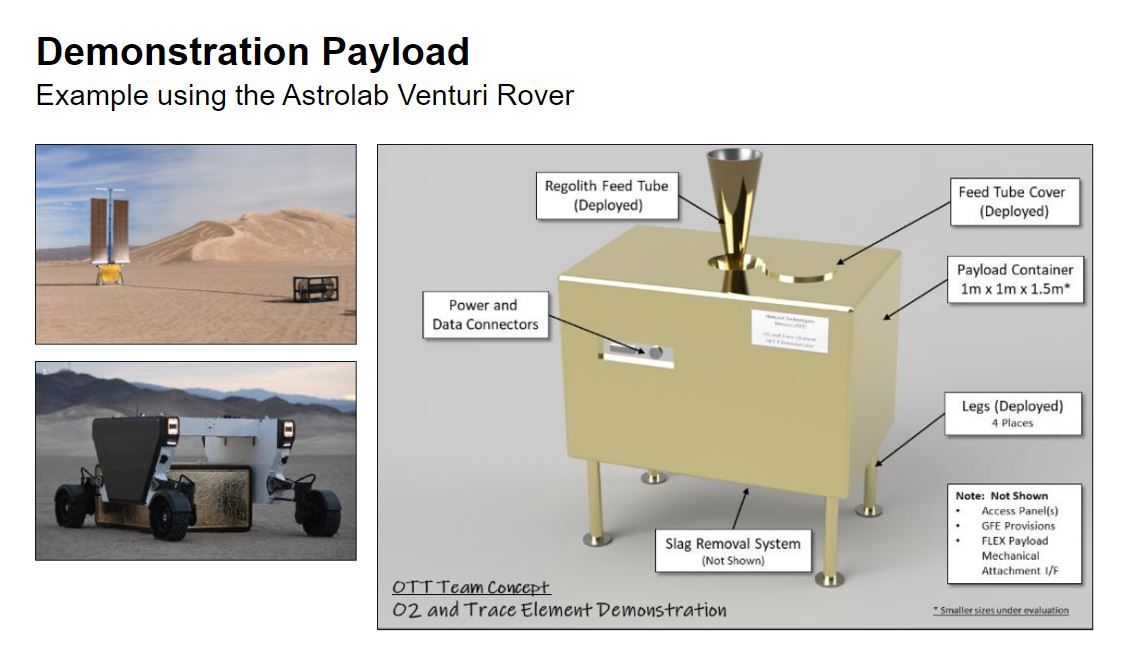

The Terraxis O2 and trace element processing reactor and associated subsystems form part of a caravan of civil engineering rovers each with a specific purpose – similar to terrestrial road construction techniques.

Terraxis revenue is generated based on the sale of regolith processing subsystems to integrated In-Situ Resource Utilization (ISRU) industrial site developers. Civil engineering machinery providers or service providers are our target markets.

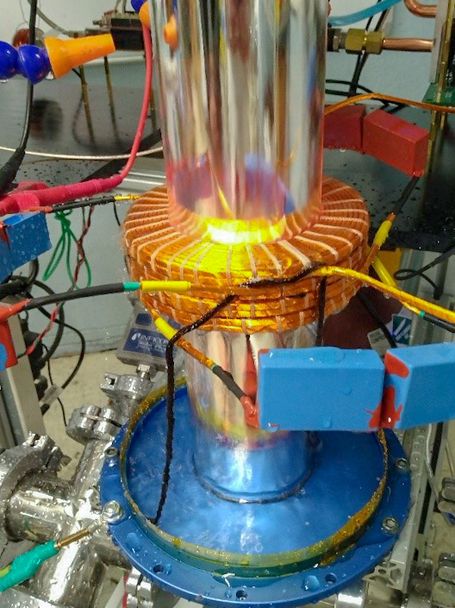

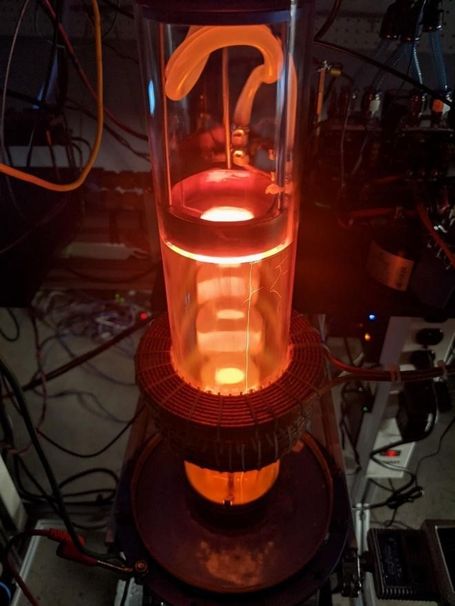

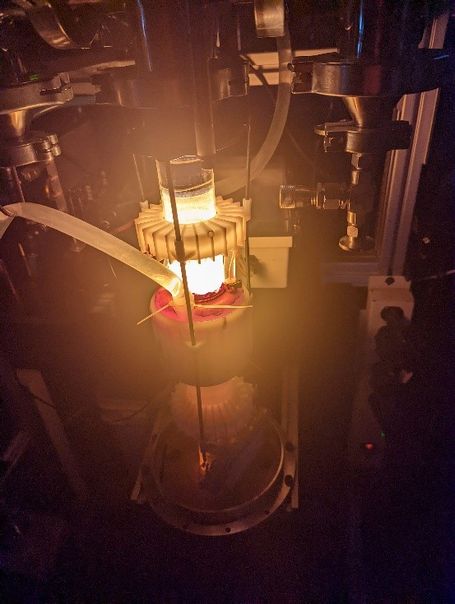

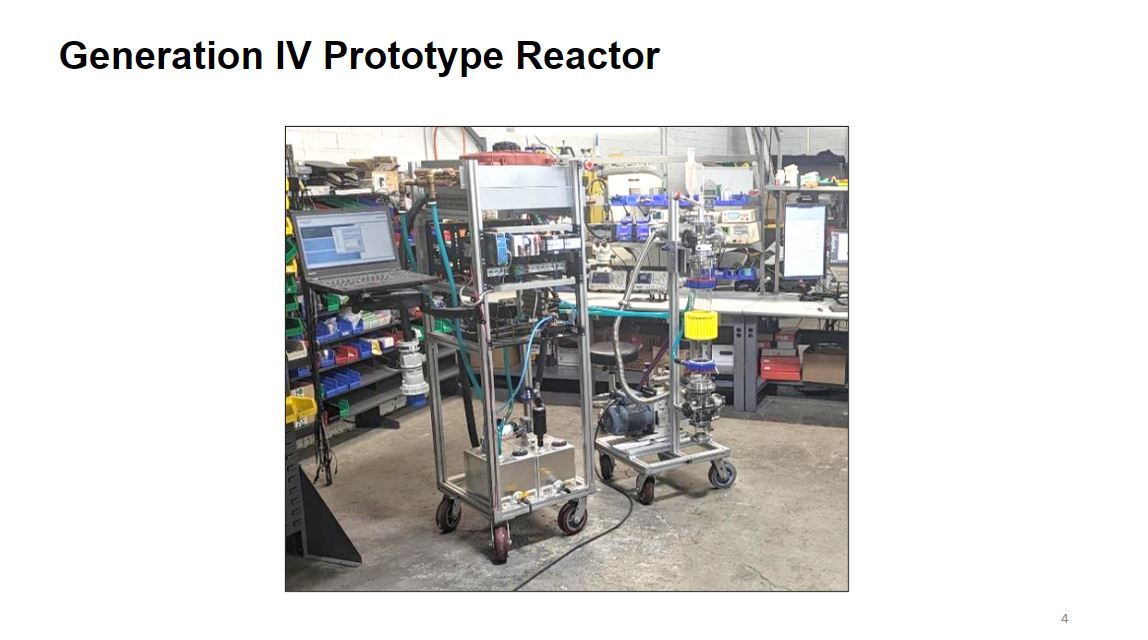

The OASIS Reactor Operational Prototype

Pictured above is the OASIS reactor operational prototype Generation 1 (G1) on the left, G2 in the middle and G3 on the right. The basis of the reactor’s simple design houses an innovative system that uses inductive power transfer to superheat a reaction chamber, a process that enables the evaporation and dissociation of lunar regolith.

G4 is currently undergoing subsystem certification testing in preparation for integrated system level testing with a regolith feed and extraction system beginning in late summer 2024.

Reactor Design

Theoretical estimates are that this reactor system design will achieve temperatures close to 3000 degrees C.

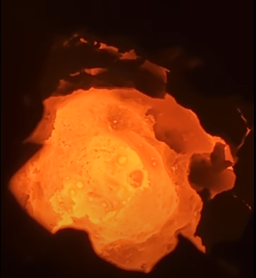

To date we have achieved temperatures exceeding 2000 C for periods in excess of 3 hours. We have vaporized lunar simulant in vacuum and demonstrated the liberation of O2.

Top image: G4 OASIS Reactor System System; Bottom Image: View Looking into Reactor 2

Bottom left to right: 1) Liberalization of O2 from Regolith Simulant; 2) metals produced during a 3-hour test; 3) Induction levitating free floating molten regolith simulant.

Technical Demonstration Public Information/7.20.2024

Oxygen/Resource Acquisition System In-Situ (OASIS)

The Future of In-Situ Resource Utilization

2500C

Theoretical

Maximum Operating

Temperature 3000C

Extractable

Elements

O2, Fe, Al, Mg,Ti,

Si, Mg, Ca

9000 kg/year

Resource Extraction

(Theoretical)

Terraxis Facilities

Northglenn, Colorado

The Terraxis industrial facility is located in Northglenn, Colorado. Northglenn is less than ten miles from downtown Denver. Our facility provides approximately 2500 square feet of floor space for design, production and test of complex prototype electronic subsystems. Terraxis has added equipment to support the goals of lunar regolith processing and efficient oxygen and metal extraction. Our capabilities are centered around a comprehensive suite of tools and equipment, enabling us to advance technology for lunar missions and beyond.

Advanced Pyrolysis Reactor

Our state-of-the-art pyrolysis reactor demonstrates our innovative approach to lunar regolith processing. Capable of reaching temperatures up to 2500°C in a vacuum, it can inject up to 80kW of heat directly into molten regolith. The reactor features a 250cc feeding apparatus, a dedicated slag chamber, and the ability to maintain a rough vacuum from 1Pa to 1000Pa. It is equipped with a gas outlet to allow atmospheric pressure for sample gas collection and an optical viewport for direct observation of the melt. The transparent side of the reactor provides an unobstructed view of the melting process. Slag extraction provisions are provided at the base of the crucible. The reactor’s drive electronics enable real-time monitoring of electrical losses and energy injection.

Electronics Laboratory

Our electronics lab is equipped with an extensive array of measurement and assembly tools. This includes an oscilloscope, function generator, inductive soldering station, assembly-resolution microscope, spectrum analyzer, and the necessary components for assembling complex Surface-Mount Device (SMD) Printed Circuit Boards (PCBs). Additionally, our laboratory inventory includes several bench-top power supplies and two advanced rack-mounted units, ensuring robust testing and analysis capabilities.

Vacuum Technology Workshop

We maintain a vacuum parts library along with cutting-edge equipment for rapid prototyping and assembly of vacuum systems. Our resources include a variety of aluminum extrusions and specialized components essential for developing vacuum chambers and related technologies.

Machine Shop

Our machine shop features a milling machine complemented by an extensive selection of tooling, a large-capacity compressor, and a complete set of hand tools. We also offer a range of welding equipment, including MIG, stick, and TIG welders, to support diverse fabrication requirements. A 100W fiber laser with PLC control, enables precise cutting and heating for a wide range of materials.

Additive Manufacturing

We have four advanced 3D printers that are integral to our prototyping process. These printers are capable of producing detailed models, functional brackets, and various hardware components, supporting our iterative design and development cycle.

Large-Scale Assembly and Prototyping Area

Our facility has a 14-foot ceiling height and a 12-foot-tall access door accommodating large-scale projects and equipment. The facility is further enhanced by access to 120, 240, and 480V 3 Phase with a 200A service.

Design and Simulation Capabilities

Terraxis is proficient in circuit simulation, design, and Electronic Design Automation (EDA). Our team leverages state-of-the-art software for physics and magnetic simulation, along with SolidWorks, Altium, COMSOL, and PSpice, to model, analyze, and optimize our designs effectively.

Quality Control, Configuration Management, System and Industrial Safety

Terraxis production operations are governed by established quality and configuration management plans. Terraxis prepares related safety and mission assurance plans based on unique program requirements. All hazardous materials are controlled to meet industrial safety requirements.

Our Team

Andreas Jochum

President and Chief Technology Officer

Andreas, a visionary, hands-on electrical engineer with 20 years of experience is leading the engineering aspects of commercially successful product execution, including flight-qualified electromechanical systems. He has dedicated his career to multidimensional design optimization in the industrial and aerospace sectors.

The world of electro-physical systems is his natural playground. His passion began as a young age as he sought to comprehend the order, chaos and complexity of an uncontrolled and evolving childhood structure—which according to some, extended into his early thirties. His passion was set in motion when first learning about superconductors. Early on, he built a thermoelectric driven hot-cold chamber and experimented with a rudimentary electromagnet macerator. At 19, he became an early pioneer developing a video streaming service.

At 29, Andreas conceived, established, and led the operation of NicaDrone (later acquired by Altius Space Machines), a developer of Electro-Permanent Magnetic (EPM) devices. This includes the OpenGrab EPM v3 200N gripper, which was successfully commercialized, achieving a production rate of 2000 units per year and resulted in several commercial patents.

Andreas later sold the EPM technology IP to Altius Space Machines. He became a member of the Altius team to lead the electrical engineering aspects of several NASA-funded research projects, including a flight experiment flown on the International Space Station.

Founder of Terraxis

Resource availability and human advancement has for all of time gone hand in hand. That is true for energy that went from a few hundred Watts in the preindustrial area to the truly enormous levels needed to allow a rocket to travel to space. Raw materials and commodities have similar stories, every step function increase in availably is mirrored with a step function of civilization advancement. For example, reasonably priced steal allowed skyscrapers to be produced across the civilized world.

A direct pathway between inexpensive unconditioned electricity to refined minerals commodities out of lunar regolith, which contains the oxygen and metals necessary for assemblance of a robust lunar economy, is the holy grail that can facilitate the next step function change in human civilization.

At Terraxis, Andreas is applying his proven track record of technical innovation and design expertise to the development and integration of all of the major elements of the Oxygen/Resource OASIS. He is currently leading the development, production and test of the 4th Generation reactor, planned for an integrated test with a regolith simulant feed system, O2 measurement system, and slag extraction system in late summer 2024.

OASIS Progress to-date. Terraxis’ technical focus is on all elements of the OASIS system. “I have accepted and embraced that keeping track of performance milestones is the key element of measuring progress toward the Terraxis goal of defining and proving the capabilities of the OASIS facility by 2030. Our primary focus currently is to be prepared to deliver Reactor G4 for integrated testing by early August. To date, Terraxis has met all scheduled G4 project milestones.”

Jon Zelon

Business and Portfolio Management

Jon leads the business management, project planning, and program control activities at Terraxis. With over 40 years of diverse experience, Jon has worked with both large and small companies, providing expertise in business management, systems engineering, product development, and risk management. His focus is on defining the product vision early and then implementing the vision.

“I have worked with Andreas for more than 4 years and continue to be impressed with the progress we (Terraxis) have made. I have been a part of this development activity from concept to garage phase to where we are now – reactor generation 4 for integrated testing. We are currently finalizing our development team and supplier support infrastructure to be in a position to send a demonstration payload to the moon in the next few years.”

Jon has extensive experience in leading complex hardware and software projects for both space and terrestrial applications. He has managed the definition, development, and delivery of numerous projects, including a large commercial habitation module, a NASA human lunar lander docking/refueling mechanism, commercial Low Earth Orbit destination ConOps, commercial small satellites, and various International Space Station payloads.

Over the past five years, Jon has provided technical program definition, business management, ConOps design, and product development support to multiple commercial space companies, including Terraxis, Gravitics, Blue Origin, York, Space Adventures, and Geo Control Systems. Previously, he served as Vice President and Chief Engineer for the commercial Excalibur Almaz program, leading product development and systems integration for a space tourism complex and earning three patents in the process.

Jon's notable roles include serving as Rockwell's Director of Shuttle Houston Payload Cargo and Systems Integration, where he ensured flight readiness of all Shuttle cargo bay elements for approximately three flights per year from 1994-2000. After transitioning to Boeing, he established and led the development of ISS Flight Support Equipment, Orbital Support Equipment, Ground Support Equipment, and the first two ISS External Storage Platforms (ESPs).